Ultra Precision Scales 20x Readability - Capacities from 5 Kg (0.05g) to 90 Kg (1g)

When your process demands more than standard accuracy, Arlyn Scales delivers. Our Ultra Precision Scales are powered by patented Surface Acoustic Wave (SAW) technology, offering 10-40x the accuracy of traditional strain gauge scales while matching or exceeding the performance of costly magnetic force restoration (MFR) balances at a fraction of the price.

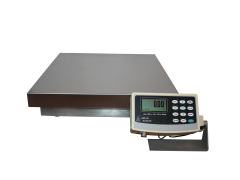

Designed and manufactured in the USA, these scales combine laboratory-grade precision with industrial toughness. With capacities ranging from benchtop models to large high-capacity platforms, Arlyn’s Ultra Precision line provides the accuracy, stability, and durability your operation needs without compromising where it matters.

In industries where even the smallest error can mean wasted materials, compliance issues, or costly rework, accuracy isn’t optional. It is critical. Traditional strain gauge scales often lack the resolution needed for sensitive formulations, while laboratory balances can be too fragile and expensive for real-world industrial environments.

That’s where Arlyn’s Ultra Precision SAW Scales make the difference:

With accuracies as fine as 0.005% of full scale and rugged platforms built for daily use, Arlyn Ultra Precision Scales deliver the confidence you need when precision isn’t negotiable.

Arlyn Scales goes beyond accuracy specs. Our Ultra Precision line is engineered to deliver real-world advantages that generic industrial scales and delicate lab balances cannot match.

Measures displacement, not strain, for 10-40x greater accuracy than standard strain gauge scales.

Achieve up to 0.00005 lb readability and 0.005% of full scale accuracy, rivaling high-end laboratory balances.

250% overload protection, stable readings across temperature swings, and rugged stainless/aluminum construction.

Ethernet, USB, RS-232, Wi-Fi, plus industrial protocols (MODBUS, PROFINET, EtherNet/IP) and AxChange cloud monitoring.

Designed, built, and supported in the USA with custom options and direct pricing with no dealer markups.

With Arlyn Ultra Precision Scales, you don’t have to choose between accuracy, durability, and cost-effectiveness. You get all three.

Choosing the right model depends on the accuracy, capacity, and environment of your operation. The table below outlines the main options in the Arlyn Ultra Precision line.

| Model | Capacity Range | Readability | Accuracy | Key Advantages | Best Use Case |

|---|---|---|---|---|---|

| Premium Ultra Precision | 10 – 100 lb | As fine as 0.00005 lb (0.02 g) |

0.005% – 0.01% FS | Highest resolution, compact bench design, 40× strain gauge readability | Chemical dosing, pharma, aerospace parts, electronics |

| Ultra Precision SAW (Standard) | 10 – 1,000 lb | As fine as 0.001 lb at 100 lb capacity |

0.005% – 0.01% FS | 10–20× more accurate than strain gauge, stable in harsh environments, multiple platform sizes | Paint and coatings, wastewater labs, nutraceuticals, industrial batching |

| Large Ultra Precision | 200 – 1,000 lb | As fine as 0.002 lb (1 g) |

0.005% – 0.01% FS | SAW accuracy on high-capacity platforms, 250% overload protection, stainless steel build | High-volume chemical production, aerospace, packaging, bulk process control |

Ultra Precision Scales are used wherever small variations can have a large impact on quality, compliance, or cost. The combination of SAW accuracy and industrial durability makes them suitable for both laboratory settings and demanding production environments.

Ultra Precision Scales are designed to fit into modern workflows. Each model is available with a range of connectivity and configuration options so that weighing data can move directly into the systems you already use.

Arlyn Scales has been developing and manufacturing precision weighing equipment for decades. Our patented SAW technology provides accuracy and durability that strain gauge and laboratory balances cannot match. Every Ultra Precision Scale is designed, built, and supported in the USA, with direct access to our engineering team.

If your requirements fall outside of standard models, we also offer custom capacities, platforms, and system integrations. Contact us to configure a solution that matches your exact needs.

Explore the full Arlyn Scales lineup or contact us today for a custom solution.

In an era of digital transformation, industries are continually seeking tools that enhance precision, efficiency, and productivity. Digital hanging scales are an innovation in scale technology and stand out as an indispensable asset for businesses. With the myriad of scale options available, choosing one might seem overwhelming. However, understanding digital hanging scales – their intricacies, … Continued

If your operations require exceptional precision when weighing products and components, then you rely on the effectiveness of your scale’s load cells. The unsung heroes of your industrial metrology equipment, do the actual work of quantifying the weight of an item. Many businesses opt to customize their load cell sensors to maximize the functionality or … Continued

Your industry may demand that you determine the best way to weigh liquids with high precision. Whether you manufacture paint or sensitive chemical mixtures, you likely require a special level of precision from your analytical balances and weighing devices at higher resolutions than other manufacturers. If you use liquefied gasses as part of your industrial … Continued

Find the right portable gram scale for your business. Scales used for commercial and industrial purposes are available in a wide variety of different sizes, weight capacities, and configurations. Some can handle additional weight and deliver consistent results with proper weight calibration. In the case of smaller devices, tinier gram scales are often known as … Continued

Imagine trying to live in a world where palletized shipping never became a thing. Consider that shipping pallets have greatly altered the way that almost every single type of commodity is transported. It would be almost unthinkable to live in a world that lacked this vital technology. That is why pallet scales for industrial applications … Continued

Platform scales are probably the most common measurement devices found throughout the industry. Every company that ships parts and materials will use a scale so that they can determine the weight of the package, and therefore the cost of transportation. Goods that are received by the company may be weighed on the scale to confirm … Continued

Table of Contents Types of SAW Scales SAW Scale Specifications How Does SAW Technology Work? Why You Should Use Ultra Precision Scales Who Can Benefit From Using These Scales? Benefits of Ultra Precision Scales Ready to Upgrade to Ultra Precision? Arlyn Scales’ Ultra Precision line delivers up to 10x more accuracy than strain gauge scales … Continued

Liquid gases are used across a broad range of industries. Liquid nitrogen is used in cryogenics. Argon is used in welding. The semiconductor industry uses many different liquid gases in the production of silicon wafers. These include silicon tetrafluoride, silicon tetrachloride, silane, disilane, and dichlorosilane, to name just a few. Weighing Liquified Gases In Cylinder … Continued

Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment. What’s So Special About “Intrinsically Safe”? Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. … Continued

Above all, one of the most fundamental types of industrial scales in today’s world is the crane scale. They are ubiquitous, highly useful, and accurate. Crane scales are utilized in a broad spectrum of diverse industries ranging from shipping to construction to fishing. These versatile scales are ideal for all lifting, force measurement, and weighing … Continued

Despite what the rock and scissor industries claim, not all paper is alike! In fact, there are different styles of paper, with varying weights, thickness, and materials. To regulate these different types and qualities, companies need a way to measure the weights of the paper accurately. Paper scales are designed for exactly this purpose. At … Continued

Analytical balances for laboratory research are necessary for precise results. Until now, purchasing managers at scientific laboratories and research facilities have always had to make a hard choice between standard industrial scales and magnetic force restoration scales. Depending on the type of research, an industrial scale may not offer the precise, high-resolution measurements required for … Continued

Virtually every industry has a grave need for accurate scales. From merchants selling textiles to farmers offering produce — along with a variety of other workers in a wide array of different industries — they all rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety … Continued

Did you know that commercial freezers are used for a variety of industrial applications? For example, meat freezers store products at different levels of processing. Some handle steaks meant for luxury restaurants. Meanwhile, others have jerky dried and flattened for long-term storage.. From the slaughterhouse, all the way through wholesale processing, packaging, and retail distribution. … Continued

Whether you’re in the chemical or powder processing industries, you’ve probably run into a situation where you need to keep all of your drums properly weighed. Taking the tare weight, to begin with, can be very important in these situations. Once you have an accurate measure of the weight of the drum itself, you’ll be … Continued

When weighing cattle and livestock you want to be sure that the scale you are using is accurate, durable, convenient, and most importantly, animal friendly. It is of great importance to assure that your cattle is of the appropriate weight, healthy and stable for your cattle needs. At Arlyn Scales, we understand the needs of … Continued

In many different environments, hazardous wastes must be carefully controlled. These can include a wide variety of medical areas including doctors’ offices, nursing homes, clinics, and hospitals. Other types of hazardous materials, including radioactive wastes, are also carefully controlled to prevent sickness Any such refuse can endanger the public if not properly documented. That is … Continued

When it comes to mixing industrial and automotive paints, precision is the key to quality reproduction and accurate colorations. The stakes of strong manufacturing practices in this context are extremely visible, and no contractor, painting company, hardware store or individual will accept a mismatched color when they are expecting a duplicate of a former coat. … Continued

The airline industry has seen quite a few changes over the past several decades. With the introduction of the internet, airlines quickly realized that they could begin selling airline tickets online and help to reduce the costs typically associated with travel agents, and even additional call center staff. In addition to the changes in the … Continued

The digital bench scale has become one of the most popular types of weighing equipment on the market. Our offerings go above and beyond to improve performance and provide superb quality. This device is manufactured under strict regulations to ensure quality. This type of scale is widely used in many industries. Naturally, that’s helped to … Continued

Copyright © 2007-2026 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7