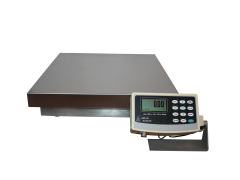

ArlynGuard B Intrinsically Safe Bench Scales - Capacities from 10lb to 150lb

In pharmaceutical and biotech manufacturing, accuracy, repeatability, and contamination control define both product quality and regulatory compliance. Whether weighing active ingredients for drug formulation or managing chemical batches in a cleanroom, every gram matters.

Arlyn Scales designs and manufactures high-precision, intrinsically safe weighing systems that meet the demanding requirements of pharmaceutical production, laboratory research, and biotechnical processing. Each scale delivers consistent readings, supports data traceability, and integrates seamlessly with your digital quality systems.

Built in our Long Island, New York facility, Arlyn Scales combine precision machined load cells, sealed electronics, and advanced Surface Acoustic Wave (SAW) technology to achieve 20× higher readability than standard strain-gauge models—while maintaining the hygiene and safety standards required in FDA-regulated environments.

Pharmaceutical and biotech operations depend on repeatable measurement across every stage of production—from R&D and pilot batches to full-scale manufacturing. Arlyn’s Ultra Precision Scales provide the accuracy and stability required for:

Each unit features corrosion-resistant stainless-steel platforms, low-noise electronics, and configurable interfaces for USB, Ethernet, or Wi-Fi communication. The result is cleanroom-ready equipment that maintains calibration integrity even after repeated sterilization or environmental cycling.

Many pharmaceutical and biotech processes involve flammable solvents, active powders, or gas-based reactants used in formulation, cleaning, or sterilization. These materials can create explosive atmospheres, requiring equipment certified for intrinsic safety.

Arlyn’s ArlynGuard Series of intrinsically safe scales is FM-approved for Class I, II, and III; Division I; Groups A through G hazardous locations, protecting both operators and facilities without compromising weighing precision.

Each system features:

These systems are ideal for pharmaceutical manufacturing zones classified as hazardous, including formulation rooms, solvent recovery areas, and compounding suites. ArlynGuard models deliver both compliance and accuracy, meeting OSHA and NFPA standards while maintaining GMP-level performance.

Pharmaceutical operations depend on high-accuracy measurement not only for formulation but also for inventory, batching, and packaging. Arlyn’s Ultra Precision SAW Scales and Counting Scales automate these repetitive weighing tasks, providing exact quantities and traceable results in seconds.

Applications include:

Using Surface Acoustic Wave (SAW) technology, Arlyn Scales achieve readability as fine as 0.05 g, detecting weight changes far below traditional strain-gauge limits. This allows pharmacists and process engineers to maintain strict dosage accuracy and product consistency across production runs.

Each system also supports memory storage for multiple product profiles, enabling operators to recall preset pill weights or formula data instantly—simplifying setup and minimizing user error.

In pharmaceutical and biotech environments, weighing accuracy must be paired with traceability and audit-ready data. Arlyn’s UpScale Touchscreen Indicator transforms precision scales into connected, compliant systems that simplify documentation and quality control.

The UpScale features a high-resolution color touchscreen with intuitive menus for quick operation in cleanroom environments. It enables real-time monitoring, automated data capture, and secure export for batch records or QA logs.

Core capabilities include:

Together, Arlyn’s weighing systems and digital indicators create a closed-loop quality framework that helps manufacturers comply with FDA and GMP standards while maintaining operational efficiency and process transparency.

Every stage of pharmaceutical and biotech manufacturing relies on measurable precision—from formulation to distribution. Arlyn Scales help teams achieve this through consistent measurement, data integrity, and process control.

Key advantages include:

Whether in sterile laboratories, R&D pilot lines, or full-scale production facilities, Arlyn Scales provide the precision and reliability necessary to maintain compliance and operational excellence in the world’s most regulated industries.

Every Arlyn system is engineered, assembled, and calibrated in our Long Island, New York facility. Using stainless-steel load cells, sealed electronics, and advanced SAW sensors, our scales deliver repeatable accuracy across thousands of cycles—resisting drift, vibration, and chemical corrosion.

From micro-ingredient dosing to bulk material management, Arlyn Scales offer stable, long-term performance trusted by leading pharmaceutical and biotech manufacturers worldwide.

In an era of digital transformation, industries are continually seeking tools that enhance precision, efficiency, and productivity. Digital hanging scales are an innovation in scale technology and stand out as an indispensable asset for businesses. With the myriad of scale options available, choosing one might seem overwhelming. However, understanding digital hanging scales – their intricacies, … Continued

If your operations require exceptional precision when weighing products and components, then you rely on the effectiveness of your scale’s load cells. The unsung heroes of your industrial metrology equipment, do the actual work of quantifying the weight of an item. Many businesses opt to customize their load cell sensors to maximize the functionality or … Continued

Your industry may demand that you determine the best way to weigh liquids with high precision. Whether you manufacture paint or sensitive chemical mixtures, you likely require a special level of precision from your analytical balances and weighing devices at higher resolutions than other manufacturers. If you use liquefied gasses as part of your industrial … Continued

Find the right portable gram scale for your business. Scales used for commercial and industrial purposes are available in a wide variety of different sizes, weight capacities, and configurations. Some can handle additional weight and deliver consistent results with proper weight calibration. In the case of smaller devices, tinier gram scales are often known as … Continued

Imagine trying to live in a world where palletized shipping never became a thing. Consider that shipping pallets have greatly altered the way that almost every single type of commodity is transported. It would be almost unthinkable to live in a world that lacked this vital technology. That is why pallet scales for industrial applications … Continued

Platform scales are probably the most common measurement devices found throughout the industry. Every company that ships parts and materials will use a scale so that they can determine the weight of the package, and therefore the cost of transportation. Goods that are received by the company may be weighed on the scale to confirm … Continued

Table of Contents Types of SAW Scales SAW Scale Specifications How Does SAW Technology Work? Why You Should Use Ultra Precision Scales Who Can Benefit From Using These Scales? Benefits of Ultra Precision Scales Ready to Upgrade to Ultra Precision? Arlyn Scales’ Ultra Precision line delivers up to 10x more accuracy than strain gauge scales … Continued

Liquid gases are used across a broad range of industries. Liquid nitrogen is used in cryogenics. Argon is used in welding. The semiconductor industry uses many different liquid gases in the production of silicon wafers. These include silicon tetrafluoride, silicon tetrachloride, silane, disilane, and dichlorosilane, to name just a few. Weighing Liquified Gases In Cylinder … Continued

Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment. What’s So Special About “Intrinsically Safe”? Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. … Continued

Above all, one of the most fundamental types of industrial scales in today’s world is the crane scale. They are ubiquitous, highly useful, and accurate. Crane scales are utilized in a broad spectrum of diverse industries ranging from shipping to construction to fishing. These versatile scales are ideal for all lifting, force measurement, and weighing … Continued

Virtually every industry has a grave need for accurate scales. From merchants selling textiles to farmers offering produce — along with a variety of other workers in a wide array of different industries — they all rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety … Continued

Virtually every industry has a grave need for accurate scales. Merchants selling textiles and farmers selling produce, along with a variety of other workers in a wide array of different industries, rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety of scales on the market, … Continued

Copyright © 2007-2026 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7