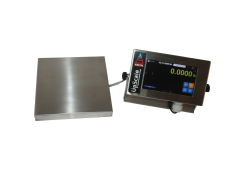

Arlyn UpScale Touchscreen Indicator - Stainless Steel Optional

Agricultural weighing applications are widespread and require industrial scales to get the job done right. For example. crops must be fertilized in a controlled manner. Too much fertilizer is wasteful and can do more harm than good. Monitoring fertilizer usage can be accomplished by weight so the mixing process of various ingredients that are incorporated into the fertilizer can require Platform Scales or Floor Scales.

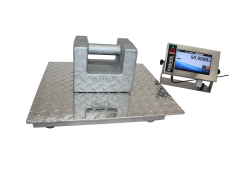

Likewise, steel cylinders of liquefied chlorine gas are used in many industrial processes. Liquefied carbon dioxide is used for the production of various chemicals, fertilizer manufacturing, and a very wide variety of other applications. Chlorination and gas feed systems are commonly used for disinfection in water, wastewater, and industrial wastewater applications. It’s also used as a bleach in the manufacture of paper, cloth, solvents, pesticides, and other commercial products.

If those corrosive materials get inside your scale, they can destroy the internal components responsible for the accuracy of your measurements. Our Corrosion Resistant Arlyn Cylinder Scales protect from corrosion. Our welded stainless steel construction, heat-treated stainless steel load cells, and garnet infused triple epoxy work together to provide you with years of accurate, trouble-free service. They also make them better able to handle tough industrial environments, protect them from shock and overloading, and make them more accurate through the use of stainless steel load cells.

Our Ultra Precision Scales allow you to automate certain manufacturing processes and monitor the level of material in your liquid gas cylinders. Our setpoint controllers allow scale owners to set up to eight weight values in their scale. Once one of these valves has been reached, the scale can turn equipment on or off via solid state relays.

You can use any of the controller’s 8 target weights to signal the start up or shut down of other equipment such as feeders, mixers, motors, valves, pumps, solenoids, and other computerized devices.

For example, a farmer can attach the set point controller to a vat of one fertilizer and use it to add the exact amount of pesticide needed. The set point controller can also be used to clear the pumps and pipes that feed liquid material into the larger mixing vat.

By setting two target weights, you can use the first to slow the feed down to a trickle and use the second to shut the pump off completely. This means you’ll get exactly the amount of liquid you need without leaving anything in the system.

And while some liquids can be monitored using a simple drum scale, this method doesn’t work for liquefied gases because the drum will appear full until the container is very nearly empty.

This doesn’t leave operators a lot of time to refill or change the container. Our set point controller can also be used to create an alert system that lets workers know in advance when a container is running low on the material so that there are no hiccups in the manufacturing process.

We’ve also recently added some additional features to our setpoint controllers. Not only can the setpoint controller be used to control equipment, but it can also be used to trigger the printing or email of certain pieces of data.

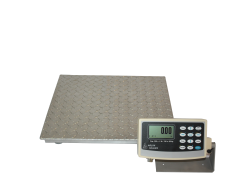

Our large precision scales are made with a diecast aluminum frame and stainless steel weighing pans. The easy-to-use indicator includes a large LCD graphics display. Some models have a zero button, 15 different weighing units and an overall design virtually guaranteed to fit your infrastructure and preferences, whether you happen to work in a hot barn, an industrial refrigerator, or any other harsh environment.

These scales are stable enough to cancel out common weight fluctuations due to temperature thanks to the technology used to create them. With a number of options depending on your preference for data transfer and storage, you can control all aspects of your fertilizer production and pesticide manufacturing. Choose options like Ethernet, WiFi, WinWedge, USB connectivity, label printing, and more.

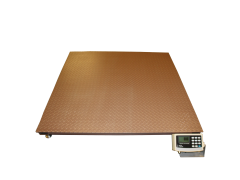

No matter what scale you use, we offer some of the lowest profile models in the industry, which makes loading and unloading a quick, simple, and painless task. We can even include on/off ramps to make it even easier.

If you’d like to learn more about Arlyn’s scale technology and how it can benefit your handling of agricultural chemicals, contact us today!

In an era of digital transformation, industries are continually seeking tools that enhance precision, efficiency, and productivity. Digital hanging scales are an innovation in scale technology and stand out as an indispensable asset for businesses. With the myriad of scale options available, choosing one might seem overwhelming. However, understanding digital hanging scales – their intricacies, … Continued

If your operations require exceptional precision when weighing products and components, then you rely on the effectiveness of your scale’s load cells. The unsung heroes of your industrial metrology equipment, do the actual work of quantifying the weight of an item. Many businesses opt to customize their load cell sensors to maximize the functionality or … Continued

Your industry may demand that you determine the best way to weigh liquids with high precision. Whether you manufacture paint or sensitive chemical mixtures, you likely require a special level of precision from your analytical balances and weighing devices at higher resolutions than other manufacturers. If you use liquefied gasses as part of your industrial … Continued

Find the right portable gram scale for your business. Scales used for commercial and industrial purposes are available in a wide variety of different sizes, weight capacities, and configurations. Some can handle additional weight and deliver consistent results with proper weight calibration. In the case of smaller devices, tinier gram scales are often known as … Continued

Imagine trying to live in a world where palletized shipping never became a thing. Consider that shipping pallets have greatly altered the way that almost every single type of commodity is transported. It would be almost unthinkable to live in a world that lacked this vital technology. That is why pallet scales for industrial applications … Continued

Platform scales are probably the most common measurement devices found throughout the industry. Every company that ships parts and materials will use a scale so that they can determine the weight of the package, and therefore the cost of transportation. Goods that are received by the company may be weighed on the scale to confirm … Continued

Table of Contents Types of SAW Scales SAW Scale Specifications How Does SAW Technology Work? Why You Should Use Ultra Precision Scales Who Can Benefit From Using These Scales? Benefits of Ultra Precision Scales Ready to Upgrade to Ultra Precision? Arlyn Scales’ Ultra Precision line delivers up to 10x more accuracy than strain gauge scales … Continued

Liquid gases are used across a broad range of industries. Liquid nitrogen is used in cryogenics. Argon is used in welding. The semiconductor industry uses many different liquid gases in the production of silicon wafers. These include silicon tetrafluoride, silicon tetrachloride, silane, disilane, and dichlorosilane, to name just a few. Weighing Liquified Gases In Cylinder … Continued

Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment. What’s So Special About “Intrinsically Safe”? Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. … Continued

Above all, one of the most fundamental types of industrial scales in today’s world is the crane scale. They are ubiquitous, highly useful, and accurate. Crane scales are utilized in a broad spectrum of diverse industries ranging from shipping to construction to fishing. These versatile scales are ideal for all lifting, force measurement, and weighing … Continued

Virtually every industry has a grave need for accurate scales. From merchants selling textiles to farmers offering produce — along with a variety of other workers in a wide array of different industries — they all rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety … Continued

Virtually every industry has a grave need for accurate scales. Merchants selling textiles and farmers selling produce, along with a variety of other workers in a wide array of different industries, rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety of scales on the market, … Continued

Copyright © 2007-2025 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7