Arlyn UpScale Touchscreen Indicator - Stainless Steel Optional

For adhesive, sealant, solvent, and resin manufacturers, there are a number of scale features that are extremely important due to how these materials are made. The process for manufacturing these products often requires mixing a number of different materials and the weight and amount used must always be tracked to ensure the finished product has the necessary sealing or adhesive properties to be used by end users.

One way that manufacturers are able to consistently create high-quality coating products is through the use of industrial scales. These scales offer a whole host of features that ensure accurate readings can be recorded and that a variety of automation procedures can be introduced that can reduce error and improve business processes all based on data from an industrial scale. Other scales we offer are explosion-proof, made for hazardous environments, including our cylinder scales for liquified gases.

At Arlyn Scales, we’ve been manufacturing high-quality industrial scales for more than 30 years. In this time, we’ve worked closely with a large number of customers to get input on their exact needs. This has allowed us to introduce a large number of specialized industrial scales and scale features that continue to be welcomed by our growing list of customers.

If you’re looking for a type of scale that will work well in the adhesive & sealant industry, be sure to check out the following models from Arlyn Scales:

Ultra Precision Scales utilize our own patented Surface Acoustic Wave technology allowing them to produce readings that are 10-20 times more accurate than standard strain gage scales while being able to provide the same level of accuracy as magnetic force restoration scales, but at a fraction of the cost. In addition, Ultra Precision Scales don’t exhibit many of the shortcomings of both strain gage and magnetic force restoration scales.

Look no further than the Ultra Precision Scale for adhesive & sealant environments where both capacity and precision are required.

Liquid gases are used across a broad range of industries, including for coatings. For both safety and general production considerations, it is extremely important to be able to monitor the level of liquid remaining in a tank to ensure that all products are being made properly. When a cylinder with liquid gas in it is placed on one of these industrial scales and the known weight of the cylinder is subtracted from the given weight, the total amount of material in the cylinder can be determined. This way the remaining liquid level in the cylinder can be constantly monitored.

There are a variety of scale features that are vital for sealant manufacturers. These features relate both to how the scales themselves are built, as well as to certain features that can make the formulation of sealants much easier. Below are just a few of the ways our industrial platform scales can be of great benefit to sealant manufacturers.

Now that we’ve showcased a few industrial scales that work well for adhesive & sealant manufacturers, here are some of the key features of our scales that make using them so beneficial to your bottom line.

Our industrial scales offer a wide array of communication options that allow you to instantly access your weight data across all types of devices on your company’s corporate network. Below are just a few of the ways that you can access weight data from one of our industrial scales:

Ethernet / WiFi – Simply connect your scale to either an Ethernet or WiFi network and instantly be able to control your scale and access weight data from anywhere.

USB – Connect a USB cable between a computer and your scale and be able to import scale data directly into a database program of your choice.

Datalogging – This data is saved in CSV format making it accessible in your favorite spreadsheet or database program such as Microsoft Excel or Access.

Another useful feature for coating manufacturers is our setpoint controller. This controller allows you and your team to better automate and control the filling, dispensing and batching of all types of materials. Program up to 8 weight values that can help you to mix and dispense materials as well as perform programmable logic (PLC) functions. This feature provides safety and convenience. Our explosion-proof scales are already one measure, but when working with volatile chemicals, every little bit helps.

When deciding to purchase an industrial platform scale to be used in the sealant manufacturing process, it’s important to understand exactly how the scale is going to be used as well as the type of materials that will come into contact with the various scale components.

If you’re in the market for a new industrial scale for your facility, we urge you to reach out to our team with any questions. We’ve been in the industry for quite a long time and feel confident that we can help you find the exact industrial scale you need at a price that is well within your budget.

In an era of digital transformation, industries are continually seeking tools that enhance precision, efficiency, and productivity. Digital hanging scales are an innovation in scale technology and stand out as an indispensable asset for businesses. With the myriad of scale options available, choosing one might seem overwhelming. However, understanding digital hanging scales – their intricacies, … Continued

If your operations require exceptional precision when weighing products and components, then you rely on the effectiveness of your scale’s load cells. The unsung heroes of your industrial metrology equipment, do the actual work of quantifying the weight of an item. Many businesses opt to customize their load cell sensors to maximize the functionality or … Continued

Your industry may demand that you determine the best way to weigh liquids with high precision. Whether you manufacture paint or sensitive chemical mixtures, you likely require a special level of precision from your analytical balances and weighing devices at higher resolutions than other manufacturers. If you use liquefied gasses as part of your industrial … Continued

Find the right portable gram scale for your business. Scales used for commercial and industrial purposes are available in a wide variety of different sizes, weight capacities, and configurations. Some can handle additional weight and deliver consistent results with proper weight calibration. In the case of smaller devices, tinier gram scales are often known as … Continued

Imagine trying to live in a world where palletized shipping never became a thing. Consider that shipping pallets have greatly altered the way that almost every single type of commodity is transported. It would be almost unthinkable to live in a world that lacked this vital technology. That is why pallet scales for industrial applications … Continued

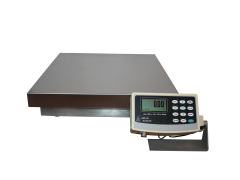

Platform scales are probably the most common measurement devices found throughout the industry. Every company that ships parts and materials will use a scale so that they can determine the weight of the package, and therefore the cost of transportation. Goods that are received by the company may be weighed on the scale to confirm … Continued

Table of Contents Types of SAW Scales SAW Scale Specifications How Does SAW Technology Work? Why You Should Use Ultra Precision Scales Who Can Benefit From Using These Scales? Benefits of Ultra Precision Scales Ready to Upgrade to Ultra Precision? Arlyn Scales’ Ultra Precision line delivers up to 10x more accuracy than strain gauge scales … Continued

Liquid gases are used across a broad range of industries. Liquid nitrogen is used in cryogenics. Argon is used in welding. The semiconductor industry uses many different liquid gases in the production of silicon wafers. These include silicon tetrafluoride, silicon tetrachloride, silane, disilane, and dichlorosilane, to name just a few. Weighing Liquified Gases In Cylinder … Continued

Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment. What’s So Special About “Intrinsically Safe”? Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. … Continued

Above all, one of the most fundamental types of industrial scales in today’s world is the crane scale. They are ubiquitous, highly useful, and accurate. Crane scales are utilized in a broad spectrum of diverse industries ranging from shipping to construction to fishing. These versatile scales are ideal for all lifting, force measurement, and weighing … Continued

Virtually every industry has a grave need for accurate scales. From merchants selling textiles to farmers offering produce — along with a variety of other workers in a wide array of different industries — they all rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety … Continued

Virtually every industry has a grave need for accurate scales. Merchants selling textiles and farmers selling produce, along with a variety of other workers in a wide array of different industries, rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety of scales on the market, … Continued

Copyright © 2007-2025 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7