Corrosion Resistant Scales For Weighing Cylinders and Drums of Corrosive Materials

If you work at or manage a wastewater treatment plant, you likely understand the need for rugged and accurate chemical weighing scales. Weighing chemicals in wastewater treatment facilities can be difficult and potentially dangerous. Furthermore, incorrectly weighing chemicals can cause significant problems for wastewater treatment plants looking to properly dispose of and treat wastewater.

When you’re looking for an industrial scale for weighing chemicals, it’s important that you choose a scale manufacturer that understands your exact needs. This includes exactly how you’re planning to use the scale, as well as the types of chemicals that the scale may come into contact with on a daily basis.

At Arlyn Scales, we’ve been pioneers in the industrial scale market for the past 30 years. We’ve helped a variety of our customer’s purchase scales that could safely weigh chemicals of all varieties. Whether you need to weigh extremely small amounts or are interested in weighing large drums full of chemicals, we have a weighing solution that can meet your needs.

Certain work environments contain materials that are too corrosive for standard industrial weigh tanks, drums, and scales. This is especially common at the water and wastewater treatment plants. When water and wastewater are being treated, technicians often need to manipulate the pH levels of the liquids, which requires the addition of potentially caustic acidic or basic chemicals.

These plants can work with relatively dangerous chemicals like chlorine or sodium hydroxide, also known as lye. Both are caustic enough to burn and damage skin and even corrode and degrade certain metals over time. Many similar chemicals are used throughout the treatment process to remove contaminants, manage the foul odor of the water, and prepare the fluid for safe disposal.

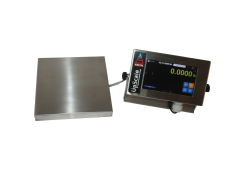

Arlyn provides corrosion resistant scales for the purpose of weighing cylinders and drums filled with corrosive materials. Whether you are weighing substances like sodium hypochlorite, alum, phosphates, or liquefied gases like chloride and sulfur dioxide, these scales can withstand spills and corrosive fumes that would destroy other scales, but this is not a complete list of the chemicals used in these industries.

The scales themselves are capable of resisting a variety of chemicals, so contact us for more information. This scale is available in six different capacities and platform sizes, meaning you are sure to find one appropriate to the scope of your industry.

Arlyn Scales are ideal for harsh industrial conditions because their load cells are constructed out of stainless steel. Many other scales are made out of aluminum or other metals. The problem with this is that aluminum is less resilient to sudden impacts, and harder to fortify against damaging materials than stainless steel is. Arlyn’s cutting-edge Surface Acoustic Wave (SAW) technology provides a degree of resolution many times higher than comparable scales on the market. Accuracy, consistency, and longevity are all marks of a scale that is worth the investment. Arlyn is confident that we deliver an excellent price point considering the quality of our products.

Our Surface Acoustic Wave (SAW) technology is one of the newest innovations that we’re most excited about, especially as it relates to certain industries like wastewater treatment facilities. This technology powers our Ultra Precision Scales and is unlike any other innovation on the market today.

Rather than measuring stress or strain, which is what strain gage scales measure, our Ultra Precision Scales measure displacement. This allows our SAW load cells to be made out of a much thicker metal, which holds up better to harsh conditions often found in applications such as wastewater treatment facilities. Furthermore, these scales offer precision weight capabilities but cost only a fraction of force motor scales, which used to be the primary option when this level of accuracy was required.

Our SAW technology is patented internationally, and is available with scale capacities of as little as 5 lbs., to as much as 1,000 lbs., all at prices that are comparable to a high-end strain gage scale, and much less than a force motor scale.

Our stainless steel surfaces are also the key to developing a scale that is resistant to corrosive materials. This coating is a polyamine epoxy. This mixture has several properties that make it an ideal choice for protecting our equipment. First, it binds well to the stainless steel we use to construct our scales. It is well suited to handling the heavy loads like drums and totes that are placed on scales, and on a chemical level, it prevents damage from corrosive materials. Our multi-step coating process includes a thick layer that binds with the stainless steel and a high-grit layer that helps with the impact resistance and prevents skidding. While some similar coatings may be affected by sunlight exposure, Arlyn’s epoxy won’t deteriorate beyond simple scuffs and fading even after many years of exposure.

It’s not just the scale itself that needs to be ready for potential spills and splashes from damaging liquids. You need your monitor and display systems to be capable of accommodating these as well. Arlyn offers a number of resilient display systems. Some of the popular and most practical options are the MKE-5 or UPSCALE-9 digital indicators. Depending on the environment, you may be interested in the NEMA 4x stainless steel display enclosure. Many of our clients who work in wastewater treatment find these upgrades make their daily work process a little smoother, easier more convenient and safer.

Many professionals choose to maximize the efficiency of their systems by exploring automation. Arlyn Scales can help with this because of our efficient hardware and software for dispensing materials in an automated fashion. This is a fantastic way to guarantee mechanical precision and consistency with your measurements. It can take repetitive and mindless tasks off your hands, which is a great way to spend your working hours more efficiently, and devote your attention to other improvements.

This is a better way to increase safety as well. The farther away your workers are from dangerous materials, the better. When you automate systems, there are fewer opportunities for accidents, which can happen no matter how careful and consistent your people are with gloves, aprons, ear and eye protection, and all personal protective equipment.

If you’re in the market for a new chemical weighing scale for your wastewater treatment facility, don’t hesitate to reach out to our team today for durable, reliable, accurate corrosion-resistant scales made of quality materials at the best price point Arlyn offers. If you work in the wastewater treatment industry, you can’t afford to cut corners when it comes to outfitting your stations with premium equipment.

To learn more explore our website. There you can view pictures prices, styles, options, features and more there. We believe that the more we know about you and your industry needs, the better prepared we are to outfit you with scales that will prove to be a reliable and rewarding investment.

In an era of digital transformation, industries are continually seeking tools that enhance precision, efficiency, and productivity. Digital hanging scales are an innovation in scale technology and stand out as an indispensable asset for businesses. With the myriad of scale options available, choosing one might seem overwhelming. However, understanding digital hanging scales – their intricacies, … Continued

If your operations require exceptional precision when weighing products and components, then you rely on the effectiveness of your scale’s load cells. The unsung heroes of your industrial metrology equipment, do the actual work of quantifying the weight of an item. Many businesses opt to customize their load cell sensors to maximize the functionality or … Continued

Your industry may demand that you determine the best way to weigh liquids with high precision. Whether you manufacture paint or sensitive chemical mixtures, you likely require a special level of precision from your analytical balances and weighing devices at higher resolutions than other manufacturers. If you use liquefied gasses as part of your industrial … Continued

Find the right portable gram scale for your business. Scales used for commercial and industrial purposes are available in a wide variety of different sizes, weight capacities, and configurations. Some can handle additional weight and deliver consistent results with proper weight calibration. In the case of smaller devices, tinier gram scales are often known as … Continued

Imagine trying to live in a world where palletized shipping never became a thing. Consider that shipping pallets have greatly altered the way that almost every single type of commodity is transported. It would be almost unthinkable to live in a world that lacked this vital technology. That is why pallet scales for industrial applications … Continued

Platform scales are probably the most common measurement devices found throughout the industry. Every company that ships parts and materials will use a scale so that they can determine the weight of the package, and therefore the cost of transportation. Goods that are received by the company may be weighed on the scale to confirm … Continued

Table of Contents Types of SAW Scales SAW Scale Specifications How Does SAW Technology Work? Why You Should Use Ultra Precision Scales Who Can Benefit From Using These Scales? Benefits of Ultra Precision Scales Ready to Upgrade to Ultra Precision? Arlyn Scales’ Ultra Precision line delivers up to 10x more accuracy than strain gauge scales … Continued

Liquid gases are used across a broad range of industries. Liquid nitrogen is used in cryogenics. Argon is used in welding. The semiconductor industry uses many different liquid gases in the production of silicon wafers. These include silicon tetrafluoride, silicon tetrachloride, silane, disilane, and dichlorosilane, to name just a few. Weighing Liquified Gases In Cylinder … Continued

Arlyn Scales provides scales for all types of clients, including those that work with hazardous materials. For use in volatile areas, Arlyn Scales offers the very best in intrinsically safe and explosion-proof equipment. What’s So Special About “Intrinsically Safe”? Many industrial facilities use scales because they need to weigh materials and prepare items for shipping. … Continued

Above all, one of the most fundamental types of industrial scales in today’s world is the crane scale. They are ubiquitous, highly useful, and accurate. Crane scales are utilized in a broad spectrum of diverse industries ranging from shipping to construction to fishing. These versatile scales are ideal for all lifting, force measurement, and weighing … Continued

Virtually every industry has a grave need for accurate scales. From merchants selling textiles to farmers offering produce — along with a variety of other workers in a wide array of different industries — they all rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety … Continued

Virtually every industry has a grave need for accurate scales. Merchants selling textiles and farmers selling produce, along with a variety of other workers in a wide array of different industries, rely on accurate scales to enable them to determine proper pricing and correct quantities. Though there are a variety of scales on the market, … Continued

Copyright © 2007-2026 Circuits & Systems Inc. Arlyn Scales. All Rights Reserved. Bigcommerce Development by Optimum7