Industrial chemicals can be tough on equipment. They can corrode metal and cause damage to electronic and other components. Most chemicals will not do that, but the industrial environment has enough potential for damaging substances to be on your scale or other equipment that it is best not to take any chances. With a little knowledge, you will be able to find a scale that is tough enough to handle industrial chemicals at a price you can afford.

The Industrial Scale

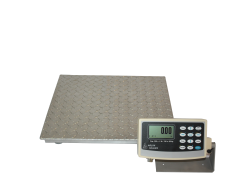

For most industrial uses, we have found through customer feedback and our own experience that the Arlyn standard 320M is a great scale for many functions within the industrial environment. It’s accurate and highly resistant to chemical spillage.

- Accuracy Ð Our platform scales are outfitted with strain gauge load cells, but these are not the standard type of strain gauge load cells that have been used for the past sixty years. Those load cells were crafted out of an inexpensive metal, such as aluminum. Some scale manufacturers still insist on this design, but this leaves them vulnerable to damage from shock and overloading. Overloading occurs when a load greater than the scale’s capacity is placed on the scale platform. Shock loading occurs when a load is dropped on to the scale platform from a significant height. Should an aluminum strain gauge load cell become damaged, it can cause significant drifts in accuracy if the scale does not become outright inoperable. The scale must then be taken out of service for repairs.

We manufacture our own load cells of stainless steel to ensure quality performance, durability, and longevity. This also helps minimize the risk of damage. Since we manufacture them at our factory, we are able to match electrical outputs from the load cells and eliminate the need for a summation board. The summation board is one of the most vulnerable points of failure in a scale’s construction. By getting rid of the summation board, you are eliminating a subsystem of the scale that could potentially be damaged by chemicals spilling onto wiring and components. The stainless steel load cells, coupled with our sophisticated design, give you an accurate scale without the vulnerabilities of inferior construction.

- Ruggedness – Our load cells are placed into protective pockets and then fitted into the four corners of the scale platform for both balance and additional protection.

The frame on our standard 320M platform is made out of aluminum, unlike the sheet metal many of our competitors use. This means that regardless of water spillage or washing, the 320M will not rust. Now, if you’re certain the scale is going to be exposed to harsh chemicals, you may wish to consider the 320M-SS platform scale. This version is designed in stainless steel so it can withstand additional corrosion that an aluminum frame may not be able to. Should you find yourself exposing the scale to chemicals that are even more corrosive, you may wish to select the 320M-CR model. It also has a complete stainless steel design; however, we increase our corrosion resistance even further by coating it with a three part, garnet infused epoxy. The base of this is a polyamine epoxy that is very resistant to most hydrocarbons, inorganic acids and alkalis, many solvents and other chemicals. It also has garnet powder mixed in to provide further protection from harsh chemicals. This also helps increase abrasion resistance and to decrease the possibility of scratching.

- High Capacities Ð These scales are not only perfect for the industrial environment because of their corrosion resistance, but also because they can handle large capacities and still maintain a desirable resolution. Our 320 Platform Scale has a lower capacity of 500 lbs. and it has a resolution of 0.1 lb while the higher capacity is 1,000 lbs. and it comes with a resolution of 0.2 lb.

Spillage Prevention and Safety

One way to reduce chemical spillage is to consider purchasing our setpoint controller. It’s a controller that allows you to enter up to eight target weight values for your scale. Once a weight value has been achieved, the setpoint controller can, via solid state relays, turn off or on any machinery. Using this controller, it’s conceivable that you could have a pump dispensing a chemical into a drum container on your scale that will shut off once the drum container has reached the target weight. By utilizing this controller, you may find that automating these types of processes can prevent chemical spills by over filling due to miscalculation of container capacities. This controller helps reduce human error and make your business more productive.

The Arlyn Scales Difference

Arlyn Scales has been designing and making scales that both provide accuracy and durability for over thirty years. Our innovative designs and superior construction have allowed us to become an industry leader. We combine the latest in cutting edge technology with quality materials, designs, and processes to ensure that you’re getting a superior product. The scales are manufactured in our factory in Long Island, New York, which allows us to ship factory direct to our customers. Our customers love it because they get to buy a quality scale at drastically reduced prices since distributors aren’t marking up the price along the way. We love it because we have a direct connection to our customers and we can sell them a higher quality scale for a reasonable price.

Outstanding Customer Support

We’ve only touched on the ways Arlyn Scales can give you an accurate scale that works in an industrial environment with potentially harsh chemicals. Should you find that you need more information, don’t hesitate to give us a call. Our courteous and knowledgeable customer service support will be more than happy to answer all your questions. Should you find the need for a more customized solution, we’ll be happy to work with you to design a scale tailor made just for you. Reach us online using the form on our Contact Us page or call us at (800) 645-4301.