If you’re handling chemicals, dosing additives, or running any process where flow rate matters, you know the smallest error can throw things off — whether it’s safety, compliance, or just getting the product right.

Most people use flow meters. But those come with assumptions — about viscosity, density, or flow consistency — and they don’t always hold up in the real world. A better approach for a lot of operations is to use an industrial scale to monitor flow by tracking how fast the material’s weight is changing over time.

That’s exactly what Arlyn Scales are built for.

Why Use a Scale Instead of a Flow Meter?

- You’re measuring the actual mass, not estimating based on density or flow speed

- It works no matter what you’re moving — from water to syrup to corrosive chemicals

- It’s safer for harsh or reactive materials

- It connects easily to pumps, PLCs, or shutoff valves to control your flow automatically

If you’re dosing, batching, or blending and need real accuracy, this gives you a direct line of sight into what’s actually moving — in real units, not rough guesses.

How It Works: Weight-Based Flow Tracking

Arlyn scales use high-resolution load cells and onboard software to calculate how much weight changes over time. From there, it converts that into a flow rate — pounds per minute, gallons per hour, whatever you need.

What makes it work:

- High-sensitivity load cells — pick up even small changes

- Timed sampling — you choose the intervals

- Manual density input — tell the system the material’s specific gravity to switch from weight to volume

- Live display — see flow rate instantly, either on-screen or remotely

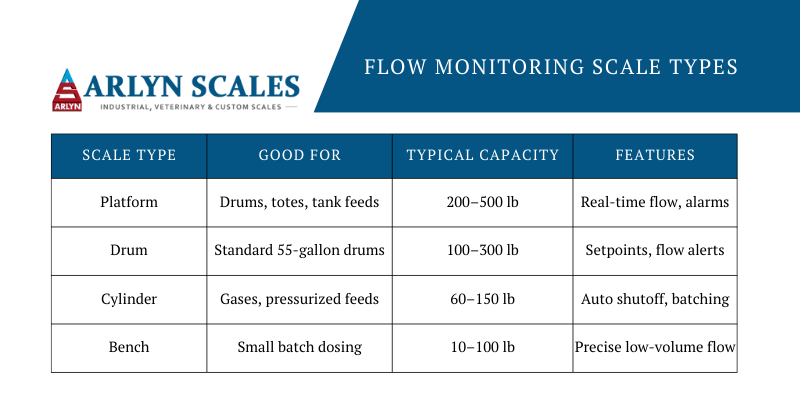

Scale Types That Work for Flow Monitoring

Where This Fits

Water Treatment – Track chlorine or fluoride flow and get alerts if things stop moving

Chemical Plants – Trigger tank switches or track batch accuracy with actual weight changes

Pharma – Keep dosing consistent, especially with small-quantity ingredients

Food & Bev – Blend liquids by weight, not time, for better repeatability

Automate the Flow (Or Stop It)

You can build real automation around this setup:

- Set high/low flow rate thresholds to trigger alarms or stop equipment

- Shut off pumps automatically when a certain amount has flowed

- Detect zero-flow situations fast, so you’re not waiting 10 minutes to find a clog

- Send alerts by screen, sound, or email — your choice

Connection Options

Whatever system you’re using, we probably integrate with it:

- Wi-Fi / Ethernet – Remote access and monitoring

- USB / Flash Drive – Local logging and data export

- RS-232 – Plug directly into PLCs or control equipment

- Cloud Logging – Optional AxChange platform for dashboards and alerts

Frequently Asked Questions

How accurate are the flow readings?

Can it handle corrosive materials?

Can I automate shutoff?

Do I get flow in weight or volume?

Let’s Get Your Flow Under Control

If your current system is making assumptions — or just doesn’t feel reliable — there’s a more direct way to manage it. With weight-based flow monitoring, you’re measuring what actually matters.

Give us a call at 866-939-4970, or get in touch online. We’ll help you figure out what works best for your setup, no pressure.