As business costs increase and technology evolves, it becomes necessary for businesses to find ways to optimize their manufacturing processes so they can reduce costs and keep up with demands. This includes automated manufacturing for batching, mixing and filling operations; fast and effective methods of taking inventory; and quality control, packaging and shipping.

As business costs increase and technology evolves, it becomes necessary for businesses to find ways to optimize their manufacturing processes so they can reduce costs and keep up with demands. This includes automated manufacturing for batching, mixing and filling operations; fast and effective methods of taking inventory; and quality control, packaging and shipping.

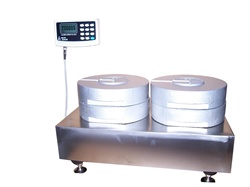

SAW Scales for Precision Measurements

While most manufacturing plants are well served by a regular industrial scale, there are some that require much more accurate measurements. This includes paint mixers and manufacturers, semiconductor manufacturers, pharmaceutical manufacturers, and those that formulate various chemical products.

These are industries where even .0001 lb of material can affect the final product. So while a normal industrial scale will be well suited to a food manufacturer (no one will care about an extra chocolate chip in their cookie, after all!), these other industries require a higher level of precision from their weighing equipment.

Yet this need can be a serious source of frustration. While regular industrial scales don’t meet this high precision need, the magnetic force restoration (MFR) scales that do are considerably more expensive, which can wreak havoc on a budget.

However, there’s finally an affordable solution that these manufacturers can use to optimize their processes without sacrificing their budget. It’s Arlyn’s line of Ultra Precision Scales, which utilizes internationally patented surface acoustic wave (SAW) technology to achieve sensitive weight readings.

Compared to a typical industrial scale with a 100 lb capacity and a resolution of 0.02 lb, a 100 lb capacity SAW scale has a resolution of .001 Ð a 20 times increase in accuracy!

And while MFR scales feature similar advantages in terms of accuracy, they’re also not well suited for industrial environments because they’re sensitive to drifts in temperature, changes in air current and vibration. Arlyn’s SAW scales are made for use in difficult industrial environments and cost about 2/3 less than MFR scales.

Counting Scales for Inventory of Small Parts

An important part of manufacturing is keeping an active and current inventory of your materials. If you use extremely small, lightweight parts, inventory can quickly become a tedious process. However, Arlyn also manufactures counting scales that can be used to convert the weight of a batch of parts into the individual number of parts in that batch. It sounds like a fairly simple process, but a lot of our competitors get it wrong.

With an easy-to-use and understand menu, these scales will definitely speed up the process. You only have to take sample weights once because you can save that weight in the scale’s memory for future use. With a “Quick Count” and “Accumulate” function, even large inventories of small parts will get inventoried in record time.

If your parts are extremely lightweight, we can equip your counting scale with our SAW technology to ensure that your inventory is as accurate as possible to significantly reduce the error see with standard scales.

As an example, let’s say your parts weigh .04152 lb. You have a regular counting sca le with a maximum capacity of 100 lbs and a resolution of 0.02 lb. Your sample size is 10 parts. Your result should read .4152, but because your scale can only read to its best resolution, your result would actually read .42 lbs. This means there is an error margin of 2.5%, which would affect your inventory fairly seriously, even though it wouldn’t really affect an inventory of larger, heavier parts.

Now let’s say you’re using an Ultra Precision Counting Scale from Arlyn. You’d have the same 100 lb capacity but a resolution of 0.001 lb. If we use the same sample weight and size, your display would actually read .415 lbs. This reduces the margin of error to a mere 0.03%, which makes its effect on your inventory almost negligible.

Data Communication

Keeping records of your manufacturing operation is also an important part of the process. Your scale can be equipped with one or more communication outputs so you can transmit data the way you need to. Some of your options are:

- Ethernet or Wi-Fi: With Ethernet, you can monitor and control your scale through your local network. Wi-Fi gives you wireless access from any location in the world that has Wi-Fi. This means weights can be recorded, stored, grouped and analyzed from any location either onsite of off.

- Cloud: If you deal with so much data that you’ve moved your data to “the cloud,” or are still deciding whether you should, this option allows you to process massive amounts of data over a secure connection without hard drives or dedicated servers. This is a great choice if you have more than one location and want to compile data from all your locations in one easy-to-access space.

- USB: One of the most common choices, USB is compatible with almost any computer system or device. With our free USB remote software, you can send data from your scale directly into a Microsoft Excel spreadsheet or Access database file. You can also operate your scale through your workstation PC.

- Setpoint Output: Use this option for simple batching and PLC-type functions. Set up to eight target weights at a time and use them to power other equipment. The setpoint output can control feeders, mixers, motors, valves, solenoids and a variety of other devices. Input formulas and save them in the scale’s memory, control the output lines behavior based on the weight applied to the platform and recall them as often as you need them.

- Other: Other less common but still available options are RS-232, RS-485, 4 Ð 20 ma and other analog signals.

Contact Us

If you’re looking for a precision scale that will help you optimize your manufacturing process, contact Arlyn Scales today! We can answer your questions and help guide you to the scale that best meets your needs.